Site Map

About

INDUSTRY-LEADING CUSTOM

FABRICATOR OF FLEXIBLE MATERIALS

Founded by LeRoy and Tom Lundell in 1978, Lundell Manufacturing is an industry-leading custom converter of flexible materials and is a verified Service-Disabled Veteran-Owned Sm...

Applications

CUSTOM FOAM MANUFACTURING

A contract manufacturer and precision foam converter, Lundell Manufacturing provides engineering and custom foam fabrication of flexible composites and parts. Lundell's diverse processes produce the highest quality...

Bulk Face Shields

Protective, comfortable face shields to help protect and mask face.

Anti-fog optically clear 8 mil film

Wrap-around face shield

Protects mask and face from direct splatter, may prolong mask life

8.75" x 13.35" full length

2# density cushion...

Careers and Job Openings

Learn about careers and job openings with Lundell Manufacturing. Lundell is continuously interested in experienced, motivated and talented professionals to join our team. We offer employees a dynamic work environment, great potential for personal and...

Contact

CONTACT US TODAY

Lundell Manufacturing Corporation

2700 Ranchview LaneMinneapolis, MN 55447Fax: +1 (763) 559-4118+1 (763) 559-4114 info@lundellmfg.com

Contract Manufacturer, Capabilities

DESIGN, PROTOTYPING AND CONTRACT MANUFACTURER

A contract manufacturer, Lundell Manufacturing has experienced sales engineers, responsive customer service and state-of-the-art equipment. In addition to being a preferred 3M and Rogers converter,...

CNC Hot Wire Cutting

Lundell provides CNC hot wire cutting for relieving localized areas for clearance, bending and shaping foam parts. This process uses a thin metal wire that is heated to a high temperature for cutting custom-shaped flexible materials.

CNC Hot Wire Cutting

...

CNC Milling

CNC milling is one of the best high-speed cutting methods for foam shaping available today. Lundell provides custom CNC milling of open-cell foams and closed-cell foams into rollers or cylindrical shapes.

High precision

Ideal for small and large ...

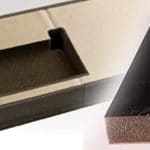

Contour Foam Cutting

Lundell offers profile cut parts produced by contour foam and flexible composite material die cutting, hot-wire cutting, water jet cutting and custom milling. Precision, intricate shapes can be created with contour cutting for a wide range of applications,...

Die Cut and Kiss Cut

Die cut and kiss cut foam parts can be manufactured using conventional flatbed presses. We are capable of providing die cutting and kiss cutting of roll goods or sheets up to 60 inch width. Lundell die cuts and kiss cuts open-cell and closed-cell foams,...

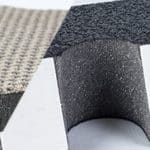

Flame Lamination

Lundell offers flame lamination of dissimilar materials, including foams such as open-cell polyester and polyether, cross-linked polyethylene. Substrates include films, fabrics, vinyls, foams, pressure-sensitive materials, plus many other materials.

...

Flatbed Lamination

Flatbed lamination is a method for laminating involving thermal adhesives that do not require long periods of curing and drying. The system is also capable of bonding multiple materials together for dynamic acoustical and thermal composites.

High-performance...

Hot Roll Lamination

Hot roll laminating uses heated rollers to melt glue in varying thickness' onto lamination films. Lundell provides hot roll lamination of pressure sensitive adhesives to most substrates. Our equipment offers adjustable speed, temperature and nip pressure...

Laser Cutting

Lundell Manufacturing offers high-precision laser cutting of various materials, including close-tolerance intricate shapes and cutouts. We offer both cutting and kiss-cutting on the same part.

Foams, films, plastics, foils, etc...

Machine capability...

Materials Testing

Lundell evaluates various materials for your application using advanced methodology in order to produce fast and reliable analysis and characterization. Our expansive lab capabilities and equipment include:

Instron tensile tester

Environmental chamber:...

Multistage Precision Rotary Die-Cutting

Lundell offers multistage precision rotary die-cutting capable of supplying parts slug- and scrap-free in manufacturing friendly rolls. We offer custom slitting, rewinding of roll goods from .060 to 60 inches. Multilevel lamination of dissimilar materials...

Prototyping

Need an early sample or model of a new concept? Or perhaps you are looking to explore an idea further? Lundell protyping can help. Our CNC programmable equipment enables us to satisfy your prototyping requirements accurately and cost-effectively.

Fast...

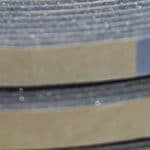

Slitting

Lundell Manufacturing provides slitting for foam stripping of open and closed-cell foams in a roll form. We are capable of providing various roll lengths and widths, supplied on 3 inch cores. Roll stock is available with and without pressure sensitive...

Slitting/Rewinding

Slitting is the process that slices rolls into thinner pieces while rewinding involves slitting materials at a tight tolerance. Lundell offers slitting/rewinding of pressure sensitive adhesives/films with slit widths from 1.5 to 60 inches and a maximum...

Specialty Assembly

We pride ourselves on offering customers a complete in-house solution, including specialty assembly. In fact, with countless years of experience, Lundell can assemble your products while minimizing costs and insuring quality and accuracy. We combine materials...

Splitting

Splitting is one of the more popular ways to alter the thickness of foam or a flexible material in order to create custom parts for your products and applications. State-of-the-art equipment provides complete material splitting capabilities, including ...

Spray lamination

Spray lamination is laminates dissimilar materials to make a flexible composite. This includes bonding of acoustical laminates to thermoformed parts. Plasticizer resistant adhesives are used to bond foam to PVC, etc.

Water Jet Cutting

Multi-axis water jet cutting machines use high-pressure water jets to cut a variety of materials. Our 5-axis water jet equipment is capable of cutting thick parts, heavy material, open- and closed-cell foams up to 10 inches thick, as well as flexible...

COVID-19 Update

An essential business, Lundell Manufacturing is continuing operations, serving customers and maintaining business continuity. We are closely monitoring the COVID-19 pandemic and taking preventative and cautionary actions to help protect employees, customers...

Encapsulated Thermal Management Pads for Electronics

ENCAPSULATED THERMAL MANAGEMENT PADS FOR ELECTRONICS

Thermal heat control in electronics is now possible without silicone oil contamination.

An alternative to low-thermal silicone-foam pads that cause oil contamination in electronics,...

Face Shield for Healthcare Workers

Protective face shields for medical and healthcare workers. Comfortable medical face shield to help protect masks and face while caring for people who may be ill.

Anti-fog optically clear 8 mil film

Wrap-around face shield

Protects mask and...

Facilities

CUSTOM FABRICATION PRECISION MANUFACTURER

A custom fabrication company, Lundell Manufacturing has state-of-the-art equipment and capabilities. Our 140,000-square foot facility is vertically integrated from first inspection of incoming...

Flexible Materials

FLEXIBLE MATERIALS

FOAMS AND COMPOSITES

A flexible materials fabricator, Lundell offers Original Equipment Manufacturers (OEMs) foam and composite parts and components engineered and fabricated to exacting specification. Every application has unique...

Google Ads

CUSTOM FOAM MANUFACTURING

A contract manufacturer and precision foam converter, Lundell Manufacturing provides engineering and custom foam fabrication of flexible composites and parts. Lundell's diverse processes produces the highest quality...

Lundell Manufacturing

CUSTOM FABRICATOR

OF FLEXIBLE MATERIALS SINCE 1978

Lundell Manufacturing is a custom fabricator of high-quality component parts made from flexible materials , including open- and closed-cell foams, silicons sponge sheets, neoprenes, vinyls, films, ...

Privacy Policy

Lundell Manufacturing Corporation recognizes that privacy is important. Lundell Manufacturing may request personal information from you via Internet forms, such as your name, e-mail address, company name, company address, telephone number, etc., to which...

Quality

DEDICATED TO QUALITY

Lundell Manufacturing’s advanced materials test laboratory is vital to our quality commitment. Laboratory failure tests on various materials , laminations and adhesive combinations all contribute to the success of ...

Request A Quote

Lundell Manufacturing Corporation

2700 Ranchview LaneMinneapolis, MN 55447Fax: +1 763.559.4118+1 763.559.4114 info@lundellmfg.com

Thank You

gtag('event', 'conversion', {'send_to': 'AW-718050846/mW5UCL2xm6wBEJ6sstYC'});

Thank You for Contacting Us

We will get back to you soon! If you need immediate assistance please call us at:

+1 763.559.4114

info@lundellmfg.com

Traverse-Wound Spooling

Lundell Manufacturing offers traverse-wound spooling to its already robust list of flexible material fabrication capabilities. Traverse-wound spooling capabilities allow Lundell Manufacturing to supply customers with continuous-length stripping products...