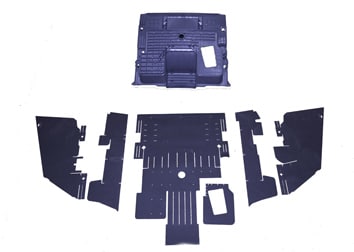

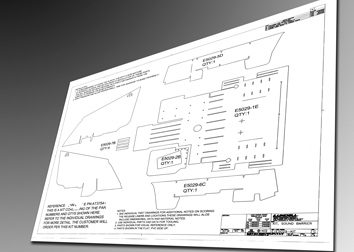

FLEXIBLE FOAM FABRICATIONS

CUSTOM COMPONENT PARTS

Lundell’s engineering, research and development team uses your design concept and modeling data to make recommendations that optimize the flexible foam fabrication process. Once we understand your application, we can then make the appropriate material recommendations and determine optimal fabricating processes. Our engineers provide expert design support for manufacturing analysis and can assist with overall product development. Our 3D printer allows us the flexibility to rapidly produce custom jigs and fixtures for your unique custom parts. In addition to prototyping using our CNC manufacturing capabilities, we provide application testing of flexible foam parts and assembly solutions to support proving your design will function appropriately for your application.