Multistage Precision Rotary Die-Cutting

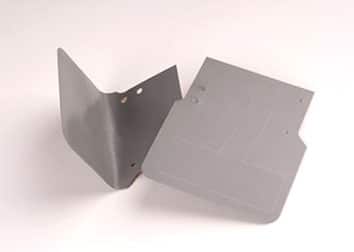

Lundell offers multistage precision rotary die-cutting capable of supplying parts slug- and scrap-free in manufacturing friendly rolls. We offer custom slitting, rewinding of roll goods from .060 to 60 inches. Multilevel lamination of dissimilar materials provides even more design options. We utilize a CAD system to maximize material usage and to reduce waste. Cutting-edge technology allows for precision multilevel cutting with multiple inline lamination die stations. Contact us with your specific application. Plastic films, foams, nonwovens, conductive foils, pressure sensitive adhesives (PSA) plus numerous other materials.

- CAD system

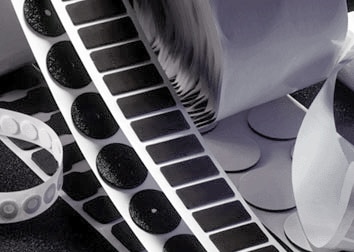

- Dry tabs

- Selective adhesives

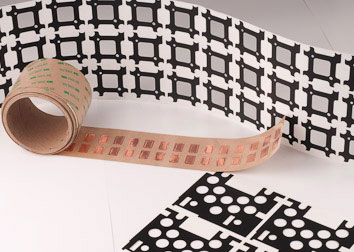

- Multilevel die cutting

- Island placement

- Inline slitting

- Multistage precision die cutting computer controlled multistage cutting capability that allows the best accuracy and repeatability

- Split liner for ease of installation

- Pressure sensitive adhesive on two sides with dry tab, for reduced labor costs

- Island placement of adhesives with corresponding split liner

- Tooling built to +/- .005

- Inline multiple material laminations in one process, with the ability to die-cut or kiss-cut each individual layer